Controlled

Freezing

Controlled rate freezing combined with cryogenic handlings area for best sample quality

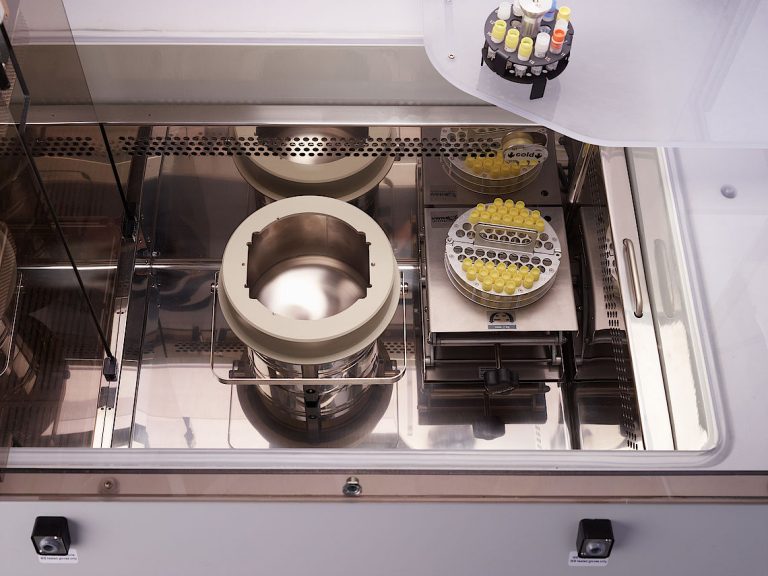

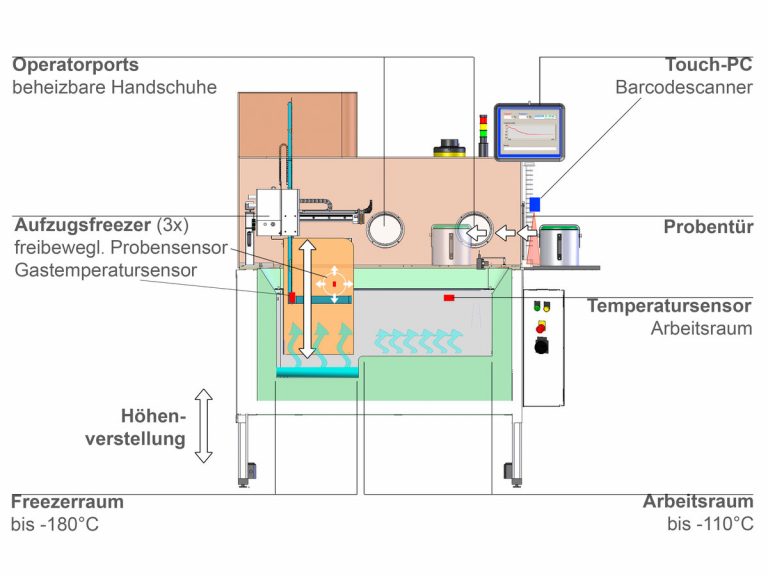

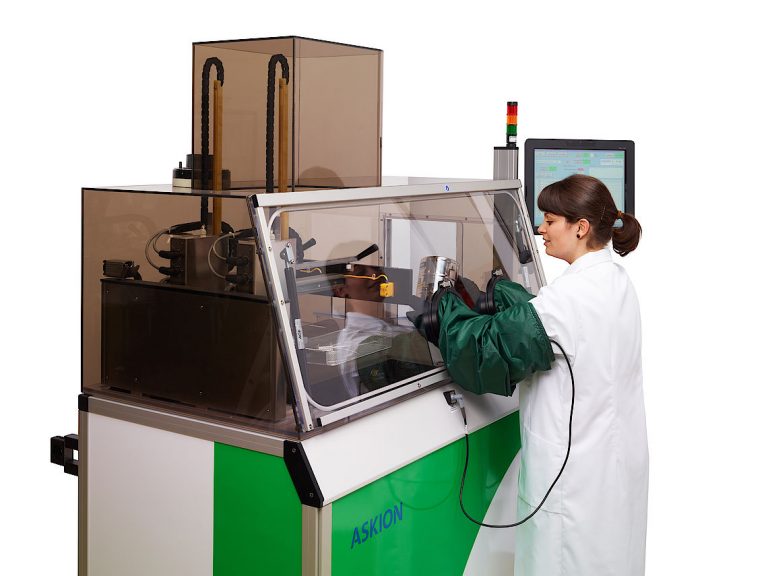

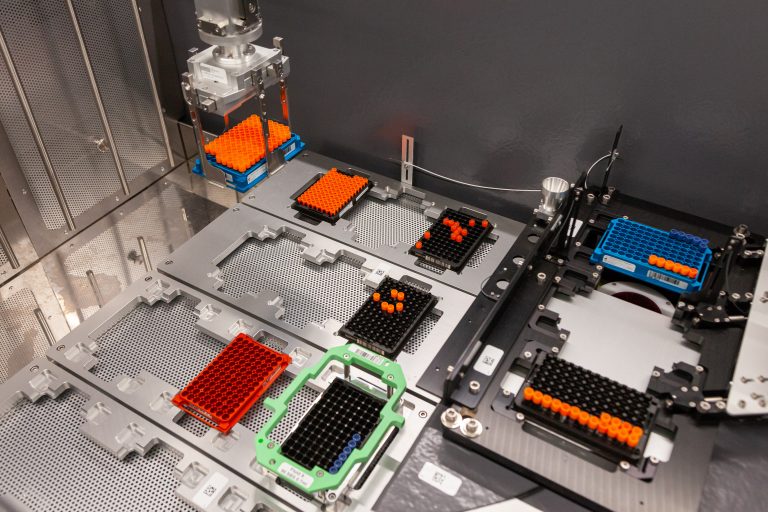

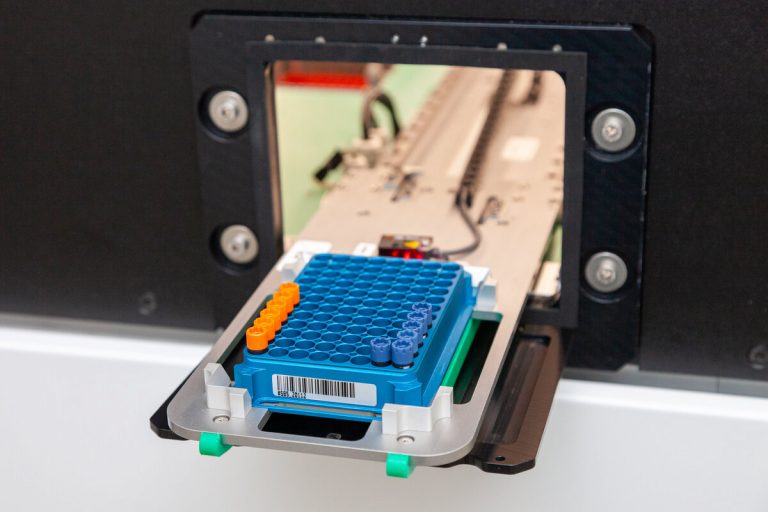

The ASKION C-line® work bench (WB) consists of a cryogenic handling area (T <-100 °C), which can be equipped with two (WB220), three (WB230) or six (aWB) controlled rate freezers. Within the cryogenic handling area, a dry nitrogen atmosphere with ultra-low temperatures is generated. These conditions allow you to sort and/or simply store your frozen samples safely without thawing and loss of sample quality. The internal/external barcode scanners allow identification and tracking of your samples at any time (barcode-based sample management).

The optional controlled rate freezers guarantee to freeze down different sample formats in a defined and reproducible manner while recording all relevant data. The controlled rate freezing can be carried out by using freely programmable freezing curves. The individual controlled rate freezers can be started at any time without having to wait for the neighboring freezer to finish their process.

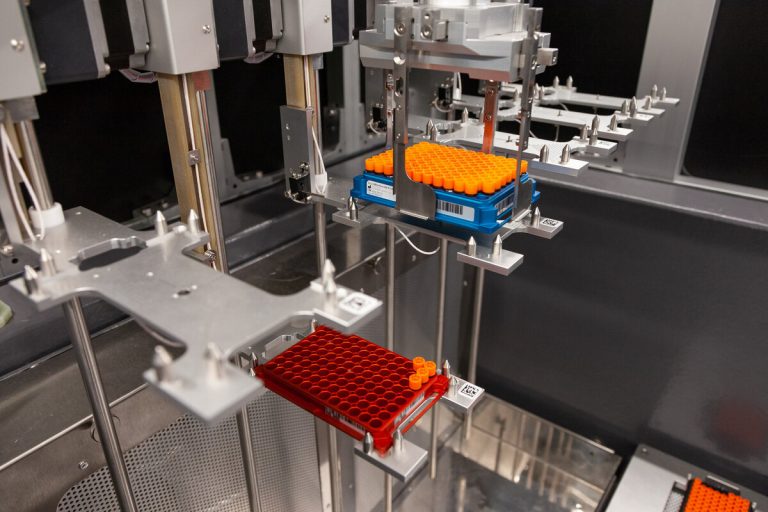

After the freezing process, you can transfer your frozen sample to the ASKION C-line® hermetic storage for storage, using a cryogenic carrier (-100 °C or colder). By doing so, a permanent cooling chain enables to archive the best sample quality for your samples. In addition to the semi-automated device, an automated workbench (aWB) is available. In this automated variant, all internal processes are carried out automatically by pick and place and SBS rack handling robots. Thanks to adaptable interfaces, the aWB can also be connected to external devices (e.g. pipetting platforms) to enable fully automated and fully documented sample processing (e.g. aliquoting, freezing, storage).

Performance features

- Controlled and reproducible freezing

- Temperature reference measurement (incl. Sample sensor)

- Up to six independently working freezers

- Freely configurable freezing curves

- Controlled seeding (targeted triggering of crystallization)

- Sample format independent

- Semi to fully automatic configuration available

- Freezer with connected cryogenic working area to handle frozen samples

- Cryogenic work room with adjustable temperature down to -130°C

- Optional automated sample handling (single samples / SBS rack) at up to -130°C

- Software and hardware supported monitoring system

Register now

Newsletter

Stay tuned and don’t miss any news about biobanking from Askion.